Featuring original designs and immaculate craftsmanship, our silk sarees are coveted by retailers across the country. A complex sari-production process that beautifully blends modern weaving techniques with the best aspects of long line of silk weaving tradition makes the visual magic possible.

Purchase Silk/Yarn

The silk yarn is purchased from trusted sources who have been known for their consistently outstanding quality. This makes our sarees distinctly superior.

Twisting

We then twist the yarn to give it strength and make them ready for dyeing.

Dyeing

This is where we infuse the yarn with mind-blowing, warm, vibrant, subdued, rich, enticing, soothing and alluring colours. We got your favourite colours for sure!

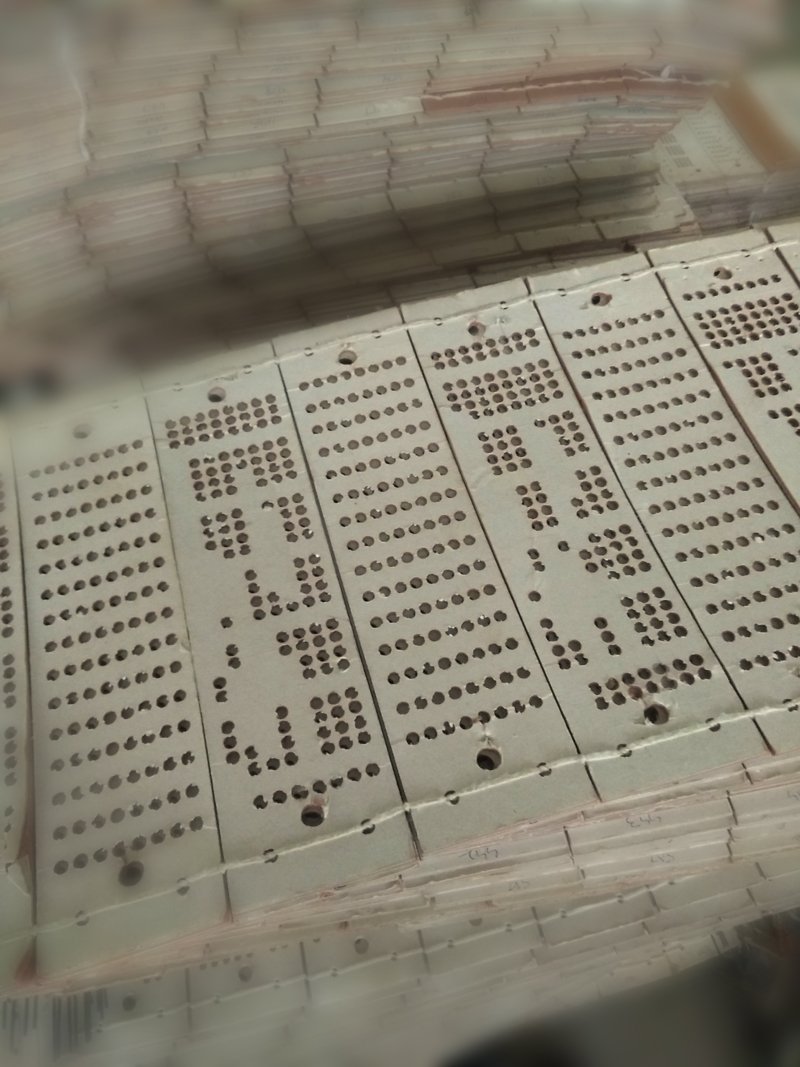

Designing and card punching

We then start creating the designs that will impress, stun and please you. We sketch them on paper and create them on computers. The design is transferred to punched cards, to be used in the looms.

Warp, Weft & Harnessing the Loom

Simultaneously, the warp (the yarn that runs lengthwise) is prepared. The warp is evenly spread and then rolled on the beam of the loom.

Weaving

The sari takes life through the focused and dedicated workmanship of the weavers. The designs on the punched card gets transferred to the yarn.

Finishing and tassel

The saris are split and then each sari is examined for quality aspects. Tassels, a universal decorative ornament in a sari, are made. The sari is now ready to go on the shelves of our retail customers.